- Details

CRC 1316 MGK Colloquium

With the start of the second funding period, all PhD students of the projects within the CRC 1316 were invited to participate in the annually MGK colloquium. The colloquium was held online at 7th and 8th of March 2022 and was organized by Maximilian Klich (project A8) and David Schulenberg (project A4).

The colloquium served as an introduction of the many new PhDs joining the CRC 1316 in its second funding period. Without the participation of project leaders it achieved a casual atmosphere for sharing scientific knowledge and interests between the PhD students. Here, they could introduce themselves and their pro- jects as well as give a short summary about their pro- jects achievements and future plans through talks or a poster presentation. Leading the talks regarding the different research topics modelling, DBD/RF discharg- es and plasma in liquids were the invited speakers which generated a well rounded experience.

The new funding period also required a few elections, namely the position of the PhD speaker formerly held by Maximilian Klich, as well as a position in the CRC 1316 gender board held by Lars Schücke (project A7) and Katharina Grosse (project B7). The newly elect- ed PhD speaker is David Schulenberg and Stefanie Bo- genrieder (project B4) as well as Lukas Forschner (project B12) are the new gender board representative.

- Details

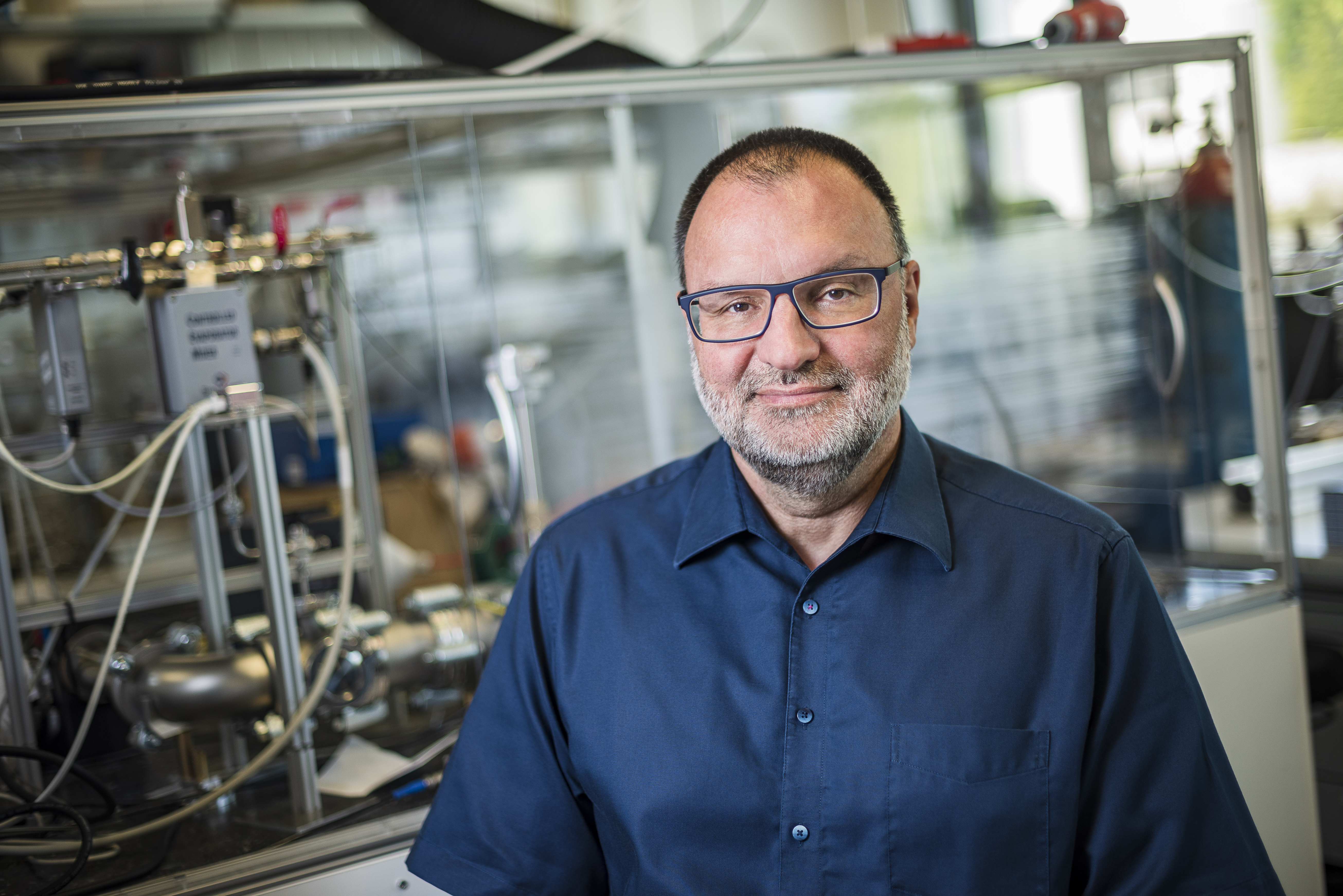

Achim von Keudell new Editor in Chief for Plasma Processes and Polymers

Achim von Keudell became with the beginning of March one of the four Editors in Chief of Plasma Processes and Polymers.

- Details

DFG approves second funding period of the CRC 1316

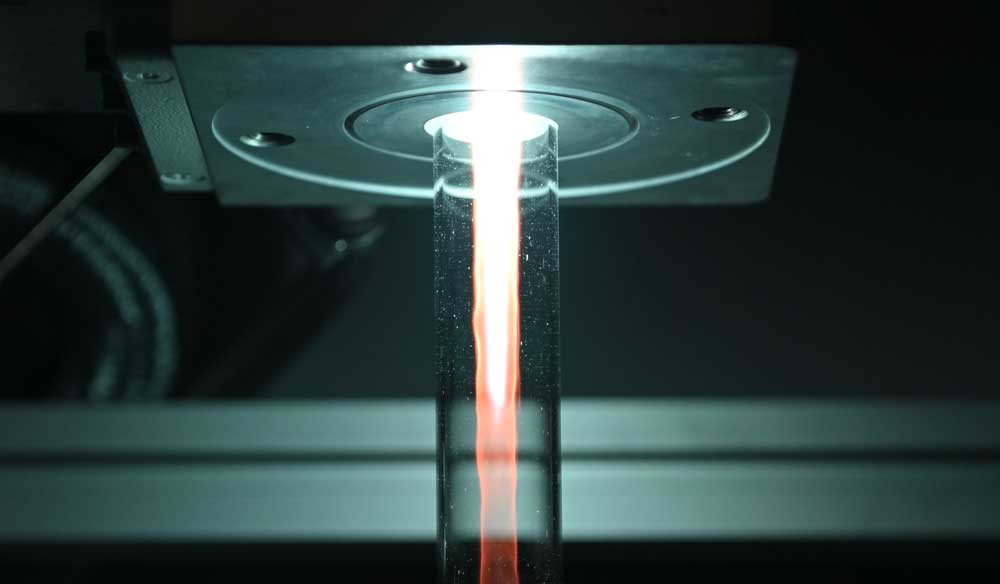

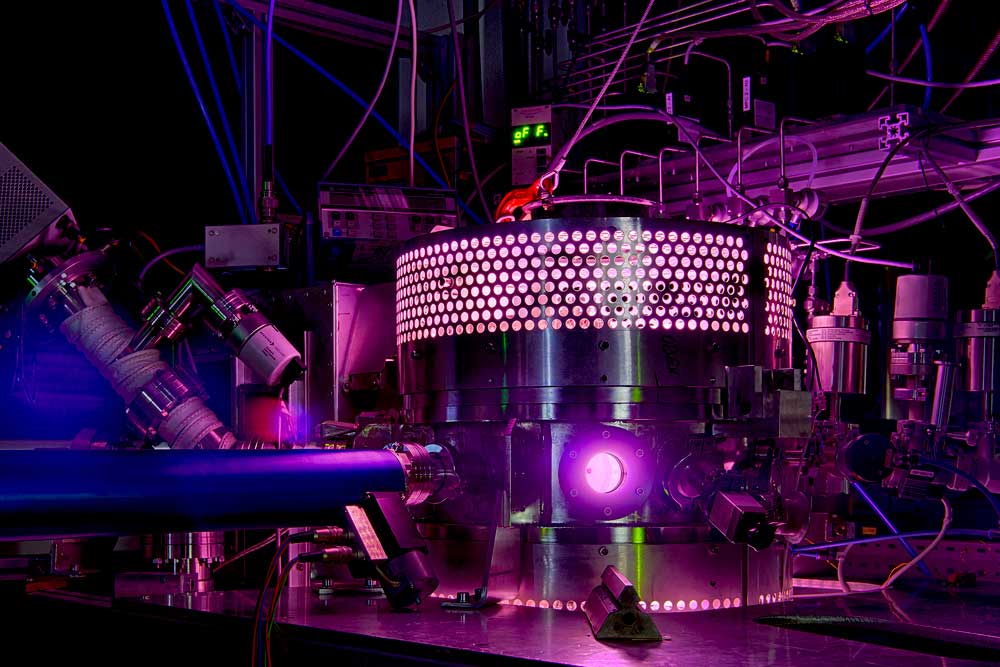

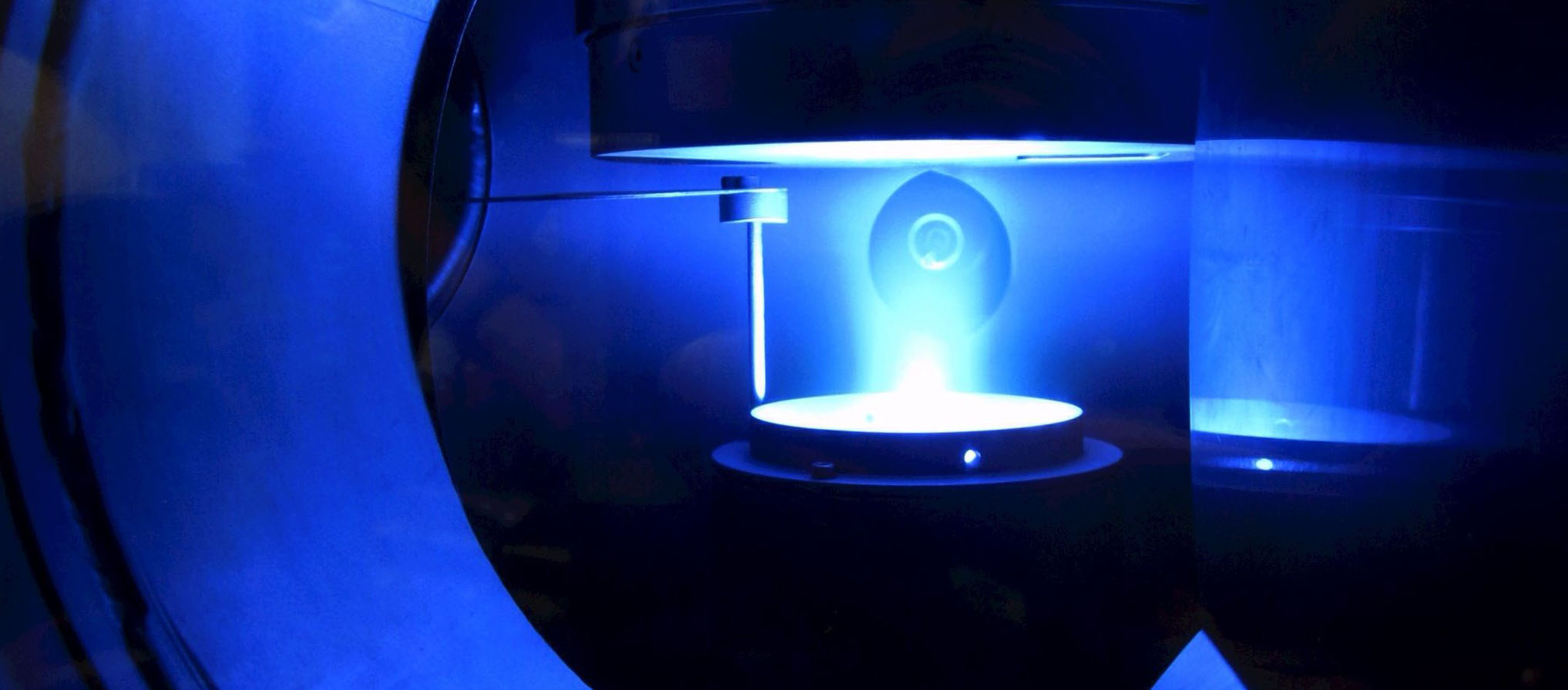

Plasmas for the Systems for material conversion are an important component in the utilization and storage of decentrally generated renewable energies. The Collaborative Research Center 1316 (CRC 1316) "Transient Atmospheric Pressure Plasmas - from Plasma to Liquids to Solids" is dedicated to combining atmospheric pressure plasmas with catalysis to develop the most flexible solutions possible for this material conversion. "They should be scalable, controllable and robust against external influences, such as impurities in the starting materials," explains Prof. Dr. Achim von Keudell, spokesman of the CRC.

The first funding period of the CRC 1316 was dedicated to the elucidation of transient phenomena in atmospheric pressure plasmas as well as interfacial processes at the surface of catalysts. Here, the focus was on three systems: the plasma-catalytic conversion of gases, the combination of plasmas with electrolysis at the interface between liquid and solid, and plasma-assisted biocatalysis, in which enzymes very selectively produce new molecules. The researchers were able to make great progress in these areas: For example, they achieved precise control of the formation of reactive particles in these plasmas. They were also able to gain a deeper understanding of the atomic and molecular surface processes in these systems.

In the second funding period, these findings will be brought together to make the best possible use of the interplay between a plasma with its reactive particles and a catalytically active surface. There are many further questions in this regard, since in traditional catalysis, for example, stable molecules are essentially reaction partners, whereas in plasma catalysis, reactive particles or highly excited species can accelerate or suppress a specific reaction path. On this basis, the first prototype plants for plasma catalysis, plasma electrolysis and plasma biocatalysis are to be developed.

In addition to the RUB as the host university, researchers from the University of Ulm, the Jülich Research Center and the Fritz Haber Institute in Berlin are involved in the CRC.

- Details

General assembly 2021

All members of the RDPCI are cordially invited to attend this year's full meeting of the Reserch Department Plasmas with Complex Interactions. It will be held on Dec. 15, 2021 at 1 p.m. via zoom.

- Details

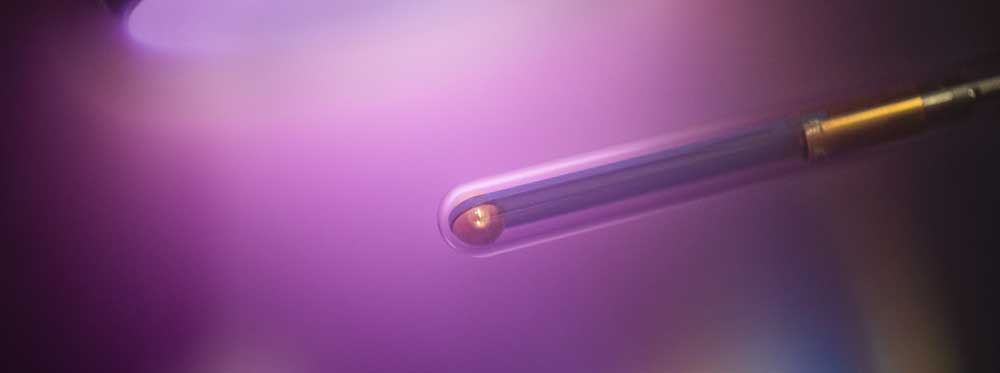

Approval for Jun.-Prof. Golda's DAAD project

In collaboration with Dr. Claire Douat from the institute GREMI in Orléans, France, Jun.-Prof. Judith Golda has submitted a DAAD project on the diagnostics and application of plasma radiation as a CO source for sterilization in wound healing. This has now been approved by the DAAD for 1.1.2022.

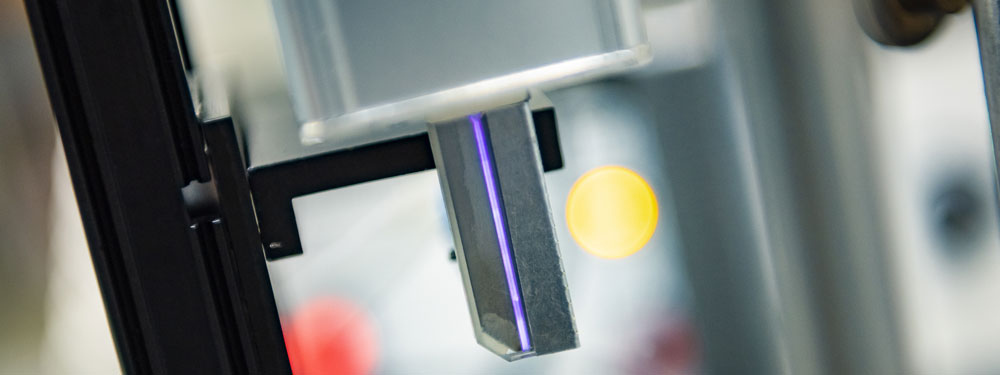

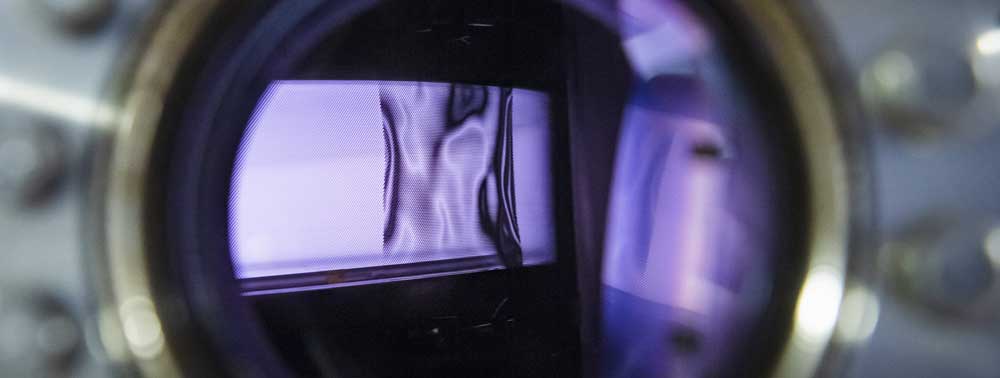

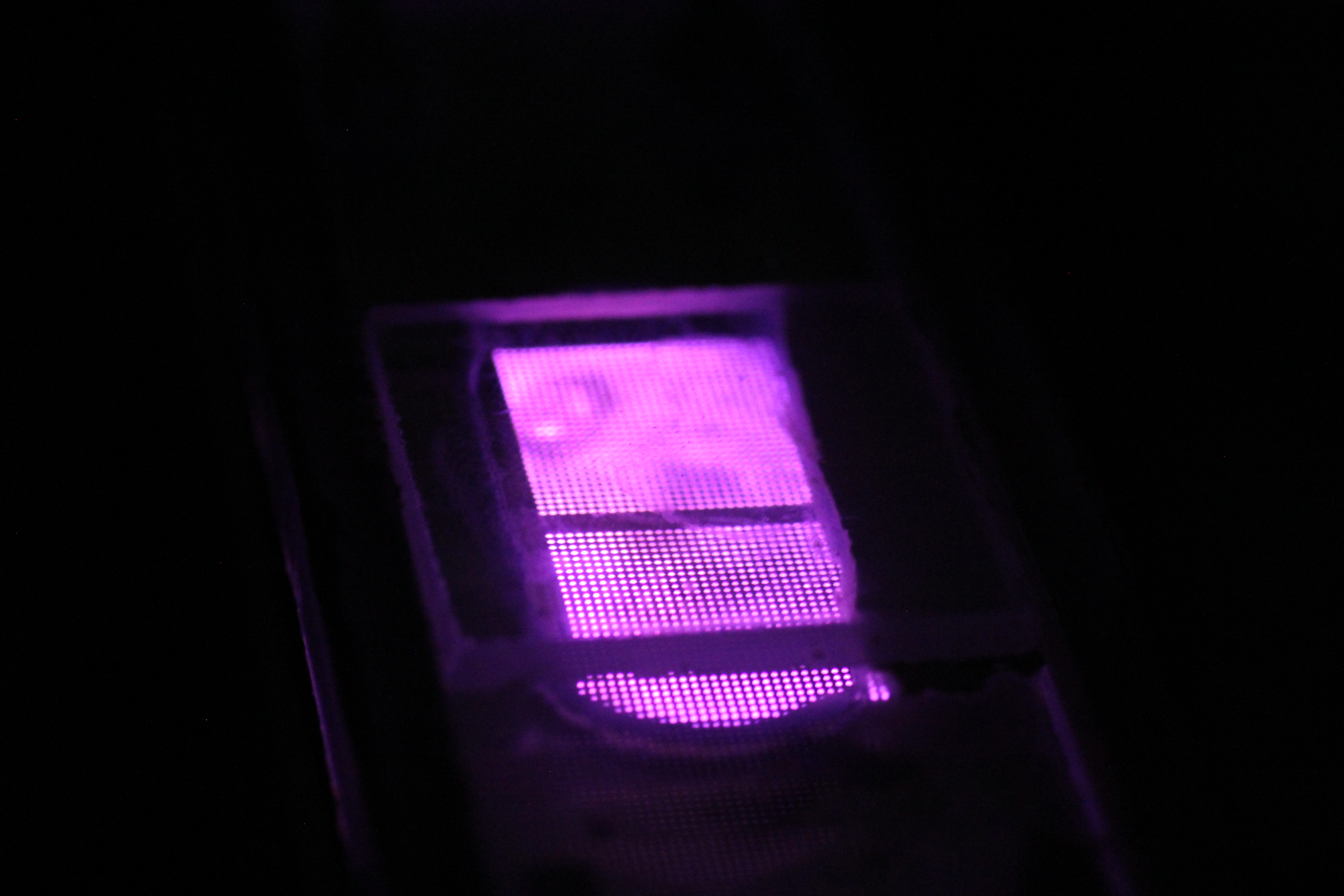

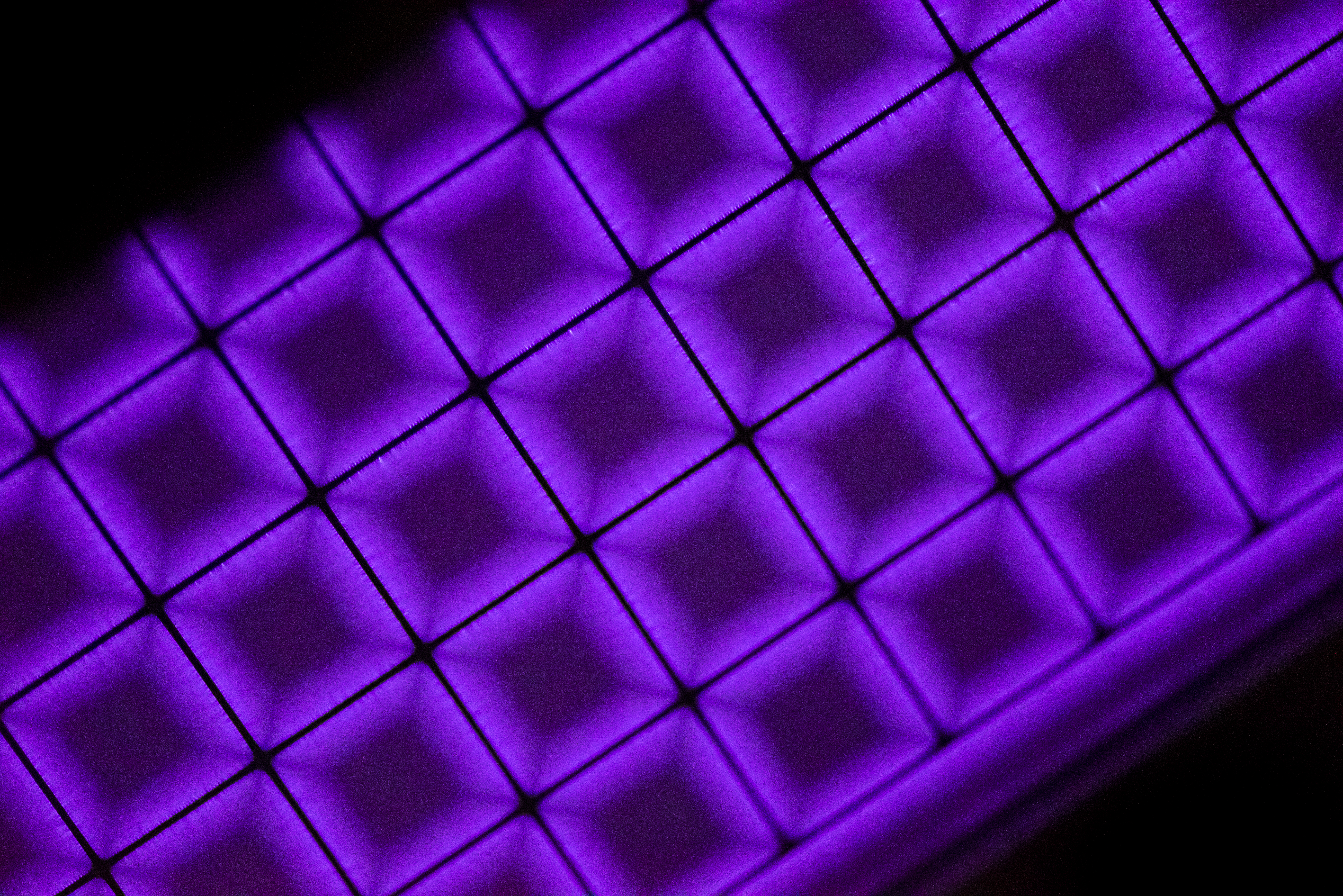

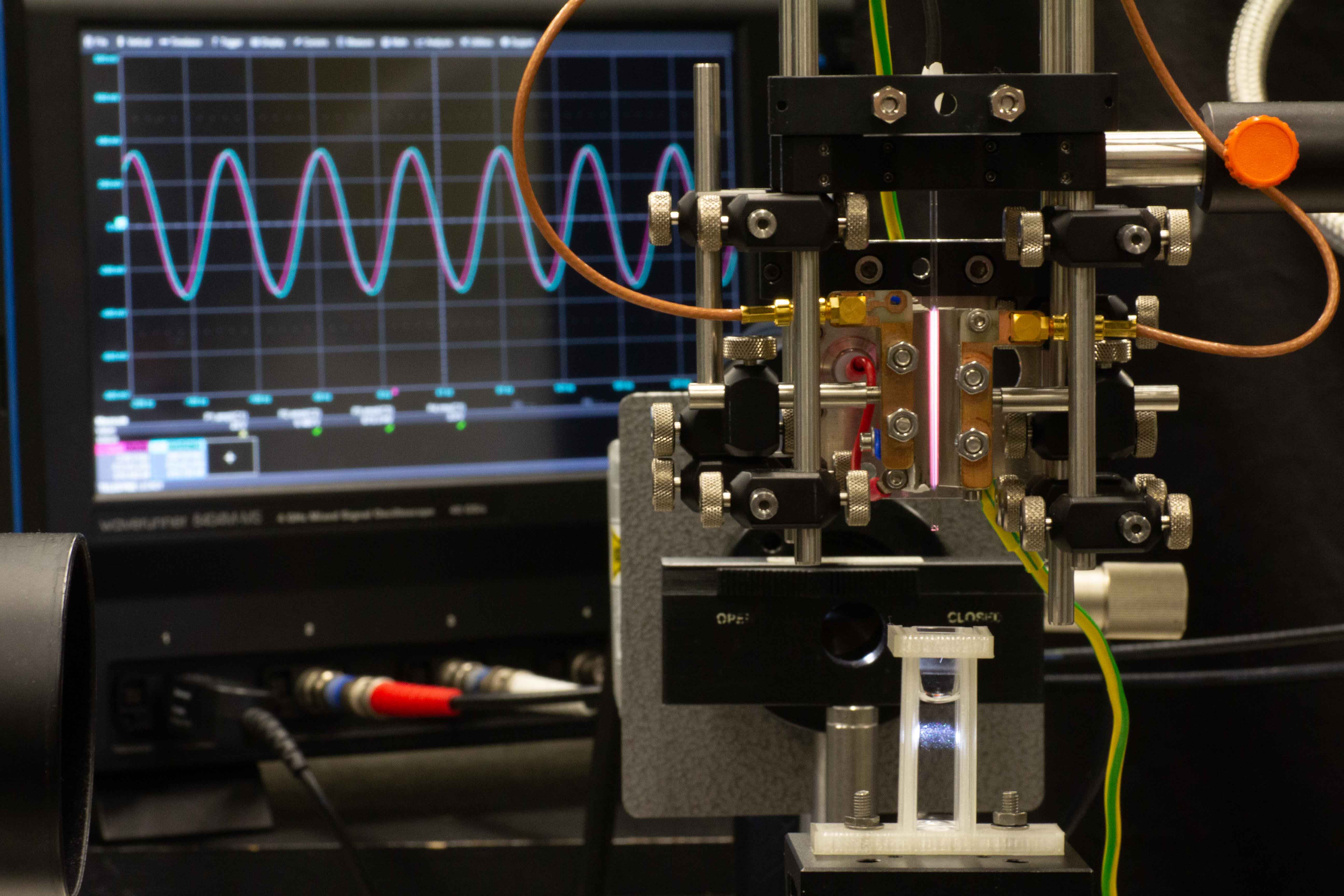

The aim of the project is to investigate the production pathways and the role of the CO molecule in the plasma treatment of biological material. To study CO generation in CAPs, two well-characterized plasma sources will be used that have complementary operating principles: A radial kHz-dielectric barrier discharge with direct contact of the plasma including ions, electrons, and strong electric fields with the treated substrate; and a coplanar RF discharge where only the field-free plasma effluent containing reactive species and plasma-generated photons reaches the substrate. This project will explore possible synergistic effects between CO and plasma-generated species such as electric fields, ions and electrons, photons, and other neutral radicals. The two complementary plasma sources will be used to distinguish the effects of indirect and direct plasma treatment on the impact of plasma-produced CO on bacteria. The plasma sources used here will be characterized with CO2 admixture to ensure that the amount of CO produced is below the toxicity limit. Parameter variations will be used to determine the optimal CO production conditions.

The project includes travel expenses to address the planned research questions.

Link to the group: https://piplab.rub.de

- Details

Japan Workshop

A workshop between CRC1316 and Japanese universities/research institutions will take part between November 29th and December 3rd, 2021. The organizers are Prof. Czarnetzki, Satoshi Hamaguchi, Jan Kuhfeld and two PhD students from Nagoya University. Further information can be found here.

Please note that the deadline is already October 27, 2021. Active participation is by invitation only, but passive participation is completely open. Participants must register in any case.

- Details

No Plasma Summer School in 2021

Due to the ongoing Covid-19 pandemic, summer school will not have been held this year. We hope it will be possible again next year.

- Details

Applied plasma research in science magazine Rubin

Our everyday lives are virtually inconceivable without plasmas. A special edition of Rubin provides insights into their numerous areas of application.

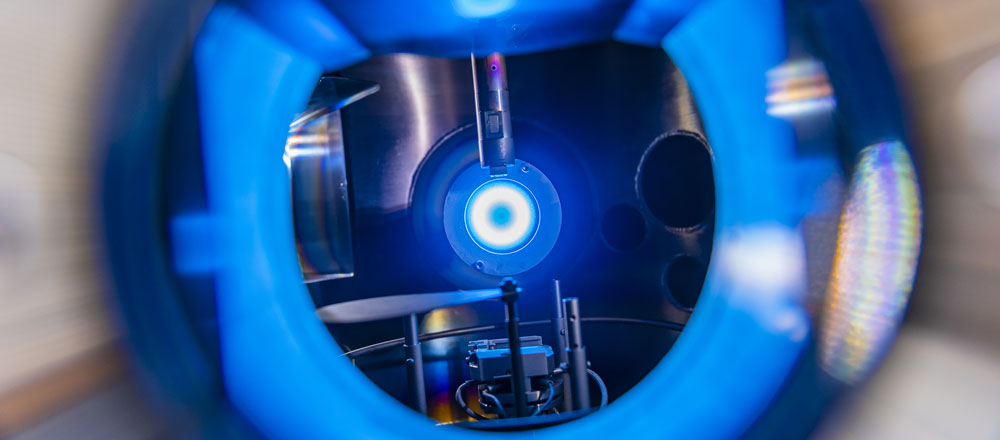

Plasmas help heal wounds, clean up exhaust gases efficiently and extend the shelf life of drinks in PET bottles. They affect our everyday lives in many ways, often without us noticing. The various applications of plasmas are featured in a special edition of Rubin, the RUB’s science magazine. The issue, published on 1 September 2021, gives insights into the activities of two Collaborative Research Centres (SFB/CRC): SFB/TR 87 “Pulsed high power plasmas for the synthesis of nanostructural functional layers” has been operating at RUB since 2010, and CRC 1316 “Transient atmospheric pressure plasmas: from plasmas to liquids to solids” since 2018. Both centres present their research in Rubin.

by Julia Weiler (RUB)

- Details

Plasmas facilitate the production of small structures

Martin Hoffmann explains why plasma processes are essential for microsystem technology and which opportunities they offer for eco-friendly manufacturing methods.

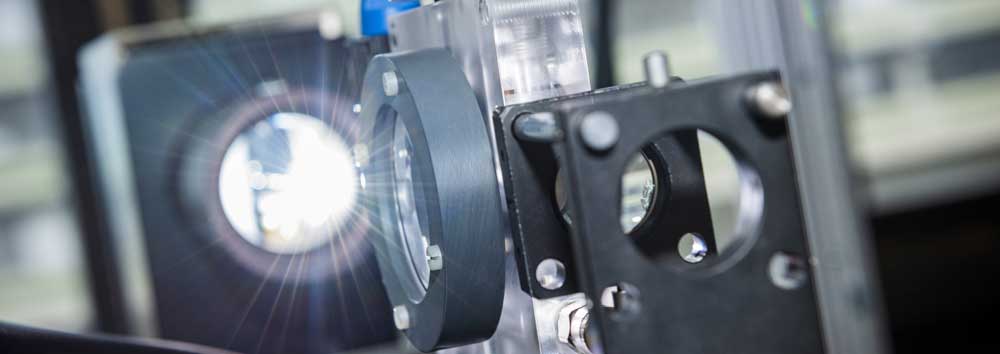

Plasmas are the tool of choice for microsystem technology. As electronic chips are getting smaller and smaller, structures can only be realized with dry, plasma-assisted processes. Wet chemical processes no longer work in these dimensions. During drying, small, movable structures are glued together by surface tension, just as two sheets of glass with a very thin film of water between them can hardly be separated. New materials such as glasses or 2D semiconductors require new processes for deposition and structuring.

The key is specially adapted plasmas. In addition, we need to significantly advance the methods for measuring the internal parameters of a plasma and the relevant process control in real time. This is the only way we can also achieve reproducible results in batch production. In addition, plasma processes offer resource-saving, environmentally friendly manufacturing methods with minimal material input – even when coating with new types of materials. This future begins now, with the construction of research facilities at the boundary between basic and applied research and cross-disciplinary cooperation to enable the use of innovative materials.

- Details

Lukas Mai receives a PhD award

Dr. Lukas Mai from the Faculty of Chemistry and Biochemistry receives a prize from the German Chemical Society (GDCh). The prize is the H.C. Starck Tungsten Doctoral Award 2021 of the GDCh Division of Solid State Chemistry & Materials Research. The prize is awarded for Mai's dissertation "Investigation of Amino-Alkyl Coordinated Complexes as New Precursor Class for Atomic Layer Deposition of Aluminum, Tin and Zinc Oxide Thin Films and Their Application." The certificate and the prize money of 2,500 euros will be awarded at the Science Forum Chemistry at the end of August.

Dr. Lukas Mai from the Faculty of Chemistry and Biochemistry receives a prize from the German Chemical Society (GDCh). The prize is the H.C. Starck Tungsten Doctoral Award 2021 of the GDCh Division of Solid State Chemistry & Materials Research. The prize is awarded for Mai's dissertation "Investigation of Amino-Alkyl Coordinated Complexes as New Precursor Class for Atomic Layer Deposition of Aluminum, Tin and Zinc Oxide Thin Films and Their Application." The certificate and the prize money of 2,500 euros will be awarded at the Science Forum Chemistry at the end of August.

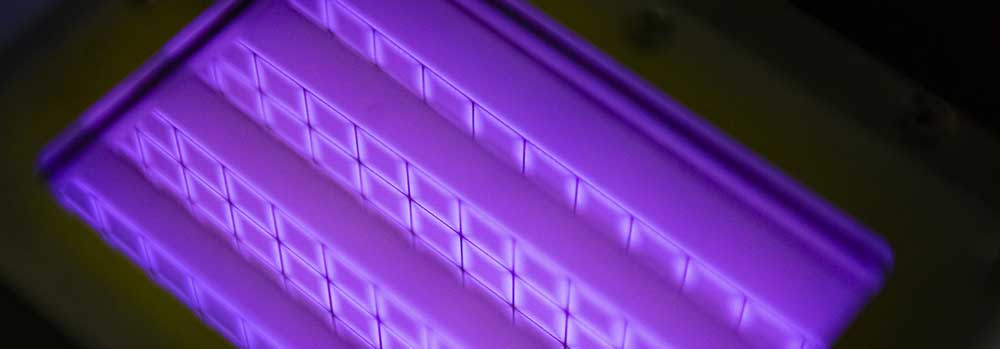

The award-winning work was carried out in an interdisciplinary environment between chemistry, materials science and engineering in the Chemistry of Inorganic Materials group. It involved the investigation of new chemicals, known as precursors, used for the deposition of ultrathin films by atomic layer deposition. These nanostructured thin films could then be tested in current applications as gas sensors, gas barrier layers or in transistors. The two projects SFB-TR 87 and EFRE-FunALD, within which the work was carried out, provided the ideal platform for this application-oriented research.

Atomic Layer Deposition is used in microelectronics for computer chips, displays and sensors, among other applications, to deposit various materials with a thickness of a few nanometers (one millionth of a millimeter) on surfaces. Chemical compounds, known as precursors, are used for this purpose, which must be volatile, thermally stable and reactive. Alkyl compounds are often used in industry, but although they meet these conditions, they self-ignite in air and thus require high safety precautions. Lukas Mai used a so-called 3-(dimethylamino)propyl (DMP) ligand to stabilize aluminum, tin and zinc compounds, which are thus safer and still meet all precursor conditions.

adapted from RUB, Arne Dessaul

- Details

Plasma generators control catalytic processes

In ten years, researchers will have understood the interactions between catalysts, which determine the speed of chemical reactions, and plasmas. This will facilitate the excitation of the plasma at atmospheric pressure in such a way that its properties accelerate the reactions on the catalyst surface in a controlled manner. As a result, chemical engineers will not only increase the turnover of the starting materials, but also the percentage of these materials that will be converted into the required product.

Therefore, the vision is that plasma generators will control catalytic processes. New compact plasma catalyst modules will be created, through which large gas flows can pass with little pressure drop. This will enable exhaust gas streams to be purified and other important industrial reactions to be carried out. In order for the modules to work in a resource-saving way, researchers still have to boost their energy efficiency. In future, catalysis, plasma and reaction engineering experts will work hand in hand to develop plasma catalyst modules. Computer-aided plasma, velocity and flow simulations will help to optimise them.

by Martin Muhler